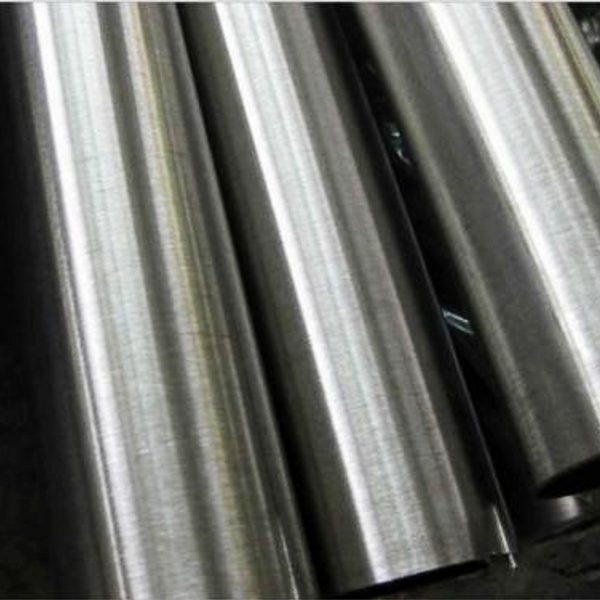

310/310S Stainless Steel Pipe

Holic® offers 310/310S Stainless Steel Pipes and Tubes of ASTM A 167, ASTM A240.

Grade 310 is an austenitic stainless steel, which offers exceptional high temperature properties, along with good ductility and weldability. Type 310 stainless steel pipes are typically used for elevated temperature applications. High chromium and nickel content of 310 grade steel pipes provides excellent resistance to corrosion and oxidation, as well as superior strength in temperatures up to 2100°F. The higher chromium and nickel content, also makes it superior to 304 or 309 stainless pipes.

Grade 310S is a low carbon alternative of grade 310. It is used in a lower temperature range when the application environment involves moist corrodents. However, the lower carbon content reduces the high temperature strength of stainless steel grade 310S compared to 310.

Item Name: 310/310S Stainless Steel Pipe.

Brand: HOLIC®.

Product Description

Type 310/310S Stainless Steel Pipe Factory:

Holic Oil Pipeline Co., LTD.

Type 310/310S Stainless Steel Pipe Basics:

Grade 310 is an austenitic stainless steel, which offers exceptional high temperature properties, along with good ductility and weldability. Type 310 stainless steel pipes are typically used for elevated temperature applications. High chromium and nickel content of 310 grade steel pipes provides excellent resistance to corrosion and oxidation, as well as superior strength in temperatures up to 2100°F. The higher chromium and nickel content, also makes it superior to 304 or 309 stainless pipes.

Grade 310S is a low carbon alternative of grade 310. It is used in a lower temperature range when the application environment involves moist corrodents. However, the lower carbon content reduces the high temperature strength of stainless steel grade 310S compared to 310.

Item Name: 310/310S Stainless Steel Pipe.

What is Stainless Steel Pipe?

Stainless steel refers to the alloy steel which can resist the corrosion of weak corrosive medium such as air, steam, water and chemical corrosive medium such as acid, alkali and salt. The corrosion resistance of stainless steel depends on the alloy elements contained in the steel. The basic alloy elements of stainless steel include nickel, molybdenum, titanium, niobium, copper, nitrogen, etc.

Stainless steel belongs to alloy steel, a kind of high alloy steel, which contains a lot of chromium, enough nickel and a certain amount of titanium. The role of chromium is to make the steel corrosion resistant, and the role of nickel is to reduce the austenitizing temperature of stainless steel. The total content of alloy elements can reach 10-28%, so it is a high alloy steel.

Advantages of stainless steel pipes

- Luster and Polishing surface

Our stainless steel is polished to ensure quality.

- Corrosion resistance

When the content of chromium atom in steel is not less than 12.5%, electrochemical corrosion can be prevented. Most stainless steel products are required to have good corrosion resistance, such as tableware, kitchen utensils, water heaters, water dispensers, etc. Some foreign buyers also test the corrosion resistance of the products.

- Excellent Solderability

Most of the finished products of stainless steel must have good weldability. Therefore, our stainless steel supplier can provide you with stainless steel with good weldability.

- Heat resistance

Stainless steel still has good physical and mechanical properties at high temperature.

Usage of stainless steel pipe

Although stainless steel pipes are higher cost to sources, according to its outstanding characteristics such as strength, anti rust, corrosion-resistance, stainless steel pipes have been applied in many industries and domains below

- Medical industry,

- Food and catering sector,

- Automotive and transportation industry,

- Construction and architecture domain,

- Energy and heavy industries.

310 / 310S STAINLESS STEEL PIPE PROPERTIES

Holic Oil Pipeline Co., LTD’s grade 310 pipes provides superior resistance to corrosion and heat, even in the most challenging environments. Following are the key feature of grade 310 pipes:

High Temperature:

Austenitic stainless steel with excellent high temperature oxidation resistance Good for continuous exposure to 2100 degree F Intermittent service to 1900 degree F.

Corrosion Resistance:

- Good aqueous corrosion resistance due to high chromium content

- Good resistance to oxidizing and carburizing atmospheres

- Excellent resistance to corrosion at normal temperatures

Heat Resistance:

- Good resistance to oxidation in intermittent service up to 1040°C temperatures, and in continuous service up to 1150°C.

- Good resistance to thermal fatigue and cyclic heating.

- Widely used in areas with elevated temperatures, and sulphur-dioxide gas.

- Continuous use in 425-860°C temperature range can deteriorate aqueous corrosion resistance due to carbide precipitation.

- Generally used in applications with temperatures starting from about 800 or 900°C.

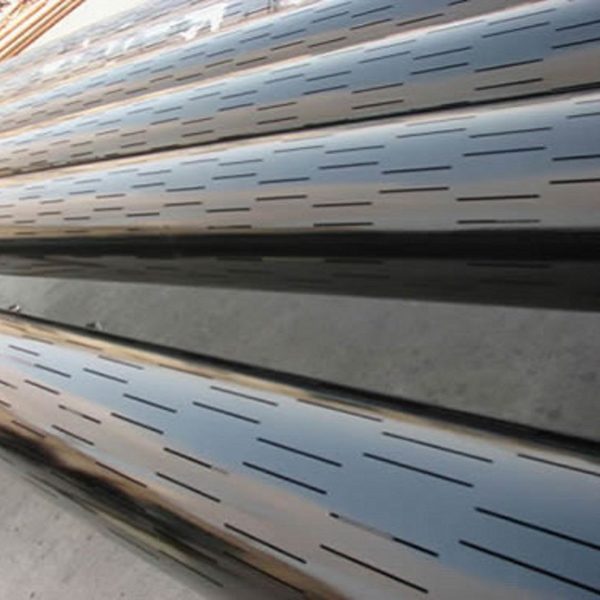

Fabrication:

- Mostly used in heat treatment and process industries in high temperature and corrosive environments

- Can be easily roller-formed, stamped, and drawn

- Usually fabricated into complex structures

- Grade 310 pipes harden after severe forming operations. Hence, it should be followed by annealing

Weldability:

- Generally weldable by common processes

- Offers weldability equivalent to 304 and 304L

Applications:

Higher alloyed 310 pipes have excellent strength at elevated temperatures. Along with this, these stainless steel grade pipes offer outstanding resistance to creep deformation and environmental contaminants. Some usage examples of 310 steel include:

- Oil Burner Parts

- Heat Exchangers

- Furnace Parts

- Welding Filler Wires and Electrodes

- Combustion Tubes

- Annealing Covers

- Fire Box Sheets

CHEMICAL COMPOSITIONS:

| Element | Type 310 | Type 310S |

| Carbon | 0.25 max. | 0.08 max. |

| Manganese | 2.00 max. | 2.00 max. |

| Sulfur | 0.030 max. | 0.030 max. |

| Phosphorus | 0.045 max. | 0.045 max. |

| Silicon | 1.50 max. | 1.50 max. |

| Chromium | 24.0 – 26.0 | 24.0 – 26.0 |

| Nickel | 19.0 – 22.0 | 19.0 – 22.0 |

Mechanical Properties:

| Type | Yield Strength 0.2% offset (KSI) | Tensile Strength (KSI) | % Elongation (2″ Gauge length) | Hardness Rockwell |

| 310 | 30 min. | 75 min. | 40 min. | HRB 95 max. |

| 310S | 30 min. | 75 min. | 40 min. | HRB 95 max. |

Our advantages:

As a leading brand of oil pipeline products in China, Holic® is working on providing high quality 310/310S Stainless Steel Pipes and Tubes with most competitive price.