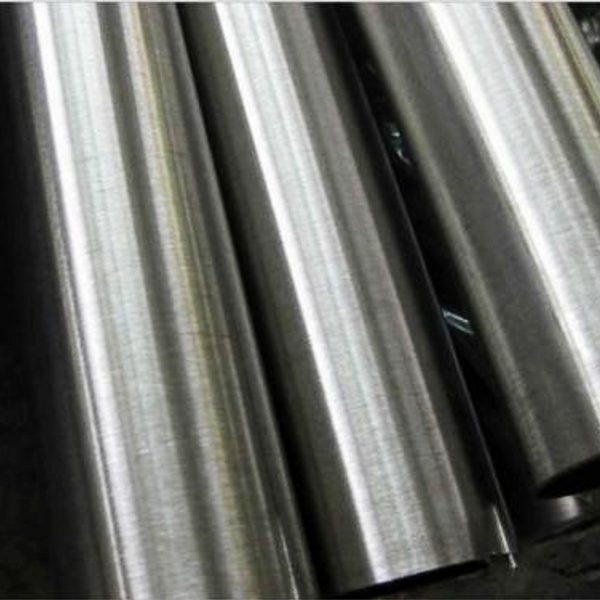

410 Stainless Steel Pipe

Holic® offers 410 Stainless Steel Pipes and Tubes of AMS 5504 and ASTM A240.

Grade 410 stainless steel is a basic, general purpose, martensitic stainless steel. It is used for highly stressed parts, and provides good corrosion resistance, high strength and hardness. Grade 410 stainless steel pipes contain a minimum of 11.5% chromium. This chromium content is sufficient enough to demonstrate corrosion resistance properties in mild atmospheres, steam, and chemical environments. Grade 410 stainless steel pipes are often supplied in hardened but still machineable condition. They are used in applications where high strength, moderate heat, and corrosion resistance are required. Grade 410 steel pipes display maximum corrosion resistance when they are hardened, tempered, and then polished.

Item Name: 410 Stainless Steel Pipe.

Brand: HOLIC®.

Standard: ASTM A240, AMS 5504

Product Description

Type 410 Stainless Steel Pipe Factory:

Holic Oil Pipeline Co., LTD.

Type 410 Stainless Steel Pipe Basics:

Grade 410 stainless steel is a basic, general purpose, martensitic stainless steel. It is used for highly stressed parts, and provides good corrosion resistance, high strength and hardness. Grade 410 stainless steel pipes contain a minimum of 11.5% chromium. This chromium content is sufficient enough to demonstrate corrosion resistance properties in mild atmospheres, steam, and chemical environments. Grade 410 stainless steel pipes are often supplied in hardened but still machineable condition. They are used in applications where high strength, moderate heat, and corrosion resistance are required. Grade 410 steel pipes display maximum corrosion resistance when they are hardened, tempered, and then polished.

Item Name: 410 Stainless Steel Pipe.

What is Stainless Steel Pipe?

Stainless steel refers to the alloy steel which can resist the corrosion of weak corrosive medium such as air, steam, water and chemical corrosive medium such as acid, alkali and salt. The corrosion resistance of stainless steel depends on the alloy elements contained in the steel. The basic alloy elements of stainless steel include nickel, molybdenum, titanium, niobium, copper, nitrogen, etc.

Stainless steel belongs to alloy steel, a kind of high alloy steel, which contains a lot of chromium, enough nickel and a certain amount of titanium. The role of chromium is to make the steel corrosion resistant, and the role of nickel is to reduce the austenitizing temperature of stainless steel. The total content of alloy elements can reach 10-28%, so it is a high alloy steel.

Advantages of stainless steel pipes

- Luster and Polishing surface

Our stainless steel is polished to ensure quality.

- Corrosion resistance

When the content of chromium atom in steel is not less than 12.5%, electrochemical corrosion can be prevented. Most stainless steel products are required to have good corrosion resistance, such as tableware, kitchen utensils, water heaters, water dispensers, etc. Some foreign buyers also test the corrosion resistance of the products.

- Excellent Solderability

Most of the finished products of stainless steel must have good weldability. Therefore, our stainless steel supplier can provide you with stainless steel with good weldability.

- Heat resistance

Stainless steel still has good physical and mechanical properties at high temperature.

Usage of stainless steel pipe

Although stainless steel pipes are higher cost to sources, according to its outstanding characteristics such as strength, anti rust, corrosion-resistance, stainless steel pipes have been applied in many industries and domains below

- Medical industry,

- Food and catering sector,

- Automotive and transportation industry,

- Construction and architecture domain,

- Energy and heavy industries.

410 STAINLESS STEEL PIPE PROPERTIES

Corrosion Resistance:

- Good corrosion resistance to atmospheric corrosion, potable water, and to mild corrosive environments

- Its exposure to everyday activities is generally satisfactory when proper cleaning is performed after use

- Good corrosion resistance to low concentrations of mild organic and mineral acids

Welding Characteristics:

- Readily welded by all standard welding methods

- To reduce the risk of cracking, it is suggested to pre-heat the work piece to 350 to 400 oF (177 to 204o C)

- After welding annealing is recommended in order to retain maximum ductility

Heat Treatment:

- The correct hot work range is 2000 to 2200 oF (1093 to 1204 oC)

- Do not work 410 stainless steel pipes below 1650 o F (899 oC)

Applications of 410 Stainless Steel Pipes

410 pipe is used where abrasion and wear resistance is needed, combined with fair resistance to general corrosion and oxidation

- Cutlery

- Steam and gas turbine blades

- Kitchen utensils

- Bolts, nuts, and screws

- Pump and valve parts and shafts

- Mine ladder rugs

- Dental and surgical instruments

- Nozzles

- Hardened steel balls and seats for oil well pumps

Chemical Composition:

| Element | Type 410 |

| Carbon | 0.08 – 0.15 |

| Manganese | 1.00 max. |

| Sulfur | 0.030 max. |

| Phosphorus | 0.040 max. |

| Silicon | 1.00 max. |

| Chromium | 11.5 – 13.5 |

| Nickel | 0.75 max. |

Mechanical Properties:

| Type | Yield Strength 0.2% offset (KSI) | Tensile Strength (KSI) | % Elongation (2″ Gauge length) | Hardness Rockwell |

| 410 Ann | 30 min. | 65 min. | 20 min. | HRB 96 |

Formability

Type 410 has reasonably good cold working properties and can be moderately drawn and formed in the annealed condition.

Heat Treatment

Annealing: Heat slowly to 1500 – 1650 °F (816 – 899 °C), cool to 1100 °F (593 °C) in furnace, air cool.

Process Annealing: Heat to 1350 – 1450 °F (732 – 788 °C), air cool.

Hardening: Heat to 1700 – 1850 °F (927 – 1010 °C), air cool or oil quench.

Follow by stress-relief or temper.

Stress Relieving: Heat at 300 – 800 °F (149 – 427 °C) for 1 to 2 hours, air cool.

Tempering: Heat to 1100 – 1400 °F (593 – 760 °C) for 1 to 4 hours, air cool.

Weldability

The martensitic class of stainless steels has limited weldability due to its hardenability. Preheating to 550 °F (260 °C) is generally not required for thin sheet sections of this lower chromium martensitic stainless steel. Post-weld heat treatment should be considered to achieve required properties. This particular alloy is generally considered to have the best weldability of this stainless class. A major difference is the lower carbon content for this alloy which eliminates the need for post-weld heat treating. When a weld filler is needed, AWS E/ER 410, 410 NiMo, and 309L are most often specified. Type 410 is well known in reference literature and more information can be obtained in this way.

Our advantages:

As a leading brand of oil pipeline products in China, Holic® is working on providing high quality 410 Stainless Steel Pipes and Tubes with most competitive price.