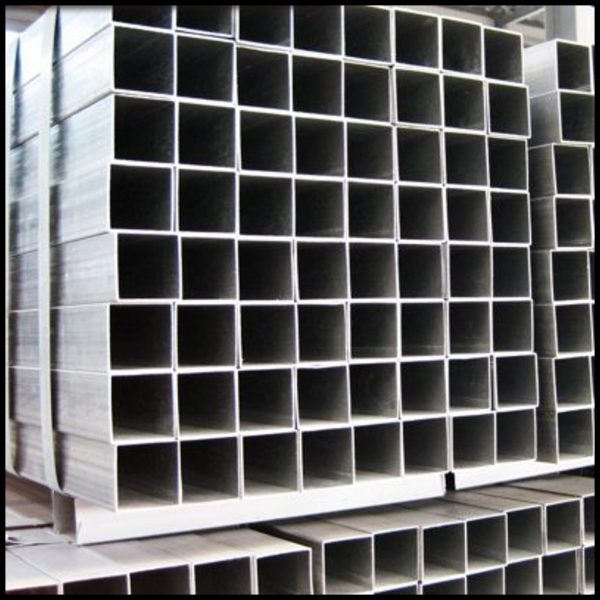

Perforated Aluminum Tubes

Holic® offers Perforated Aluminum Tubes. Perforated aluminum pipes/tubes has a strong resistance to corrosion due to an oxide skin formed in reaction with the atmosphere. It is a relatively light metal pipe compared to metals such as steel, nickel, brass, and copper and is rather malleable. It can have a wide variety of surface finishes and is highly reflective to heat and light. For most applications, perforated aluminum sheets and tubes need no protective coating but are often anodized to improve color and strength.

Item Name: Perforated Aluminum Tubes.

Brand: HOLIC®.

Product Description

Perforated Aluminum Tubes

Holic® offers Perforated Aluminum Tubes. Perforated aluminum pipes/tubes has a strong resistance to corrosion due to an oxide skin formed in reaction with the atmosphere. It is a relatively light metal pipe compared to metals such as steel, nickel, brass, and copper and is rather malleable. It can have a wide variety of surface finishes and is highly reflective to heat and light. For most applications, perforated aluminum sheets and tubes need no protective coating but are often anodized to improve color and strength.

Aluminum perforated tube is extremely useful at low-temperatures. At subzero temperatures its strength increases while retaining ductility. At temperatures over 400F aluminum alloy sheets tend to lose some of their strength.

Aluminum, like Stainless Steel, is corrosion resistant. It is, however, much lighter and softer than Stainless and Carbon Steel. To prevent the dull appearance that results from the oxidation of the outer layer, Aluminum can be either clear or color anodized after perforating. Unlike paint or powder coating, anodize film is built from the aluminum itself and takes on a translucent appearance. The alloys listed below are categorized into two types, non-heat-treatable and heat-treatable.

Perforated Patterns

The majority of the patterns shown within each section represent the most commonly used patterns that our existing tooling produces. Due to the versatility of the tools and presses, it is not practical to show every possible pattern that can be produced. Because of the vast number of patterns that can be produced from our tools, it is likely that your requirement can be fulfilled with existing tooling.

In the event we can not produce a pattern with existing tooling, the Customer Service Representative will either quote the closest alternate and/or obtain the price to have our on-site tool and die shop build a proprietary tool.

Item Name: Perforated Aluminum Tubes.

Brand: HOLIC®.

Commonly Perforated Aluminum Types:

1100 (Non-Heat-Treatable Alloys)

This commercially pure, low-strength alloy has excellent corrosion resistance and satisfactory anodizing and coating finishes. It is unmatched by any other commercial aluminum alloy in workability.

3003 (Non-Heat-Treatable Alloys)

The most widely used general-purpose alloy because of its good corrosion resistance, moderate strength, formability, and weldability. This alloy may show some slight discoloration when anodized, but reacts well to other coating finishes.

5005 (Non-Heat-Treatable Alloys)

Comparable to 3003 in strength and formability, this alloy has superior finishing characteristics, making it much better for anodizing. Excellent corrosion resistance and weldability, but rates below 1100 and 3003 for machining.

5052 (Non-Heat-Treatable Alloys)

A versatile high-strength alloy with good forming characteristics and excellent corrosion resistance. Although easily welded, it is not recommended for brazing and soldering applications. Anodized coatings may take on a yellowish tint if applied too thick.

2024 (Heat-Treatable Alloys)

An age hardening, high-strength alloy with nearly twice the strength of 5052 and fair corrosion resistance. Alclad 2024 provides improved corrosion resistance. Anodized coatings may take on a yellowish tint if applied too thick.

6061 (Heat-Treatable Alloys)

A high-strength alloy that has very good corrosion resistant, finishing, welding characteristics. Anodized coatings may take on a yellowish tint if applied too thick.

7075 (Heat-Treatable Alloys)

Developed for aircraft applications, this is one of the highest strength, commercially available alloys. It has fair corrosion resistance and machinability. Alclad 7075 provides improved corrosion resistance. Anodized coatings may take on a yellowish tint if applied too thick.

| Aluminum | Lbs. Per Square Foot | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Gauge | Mean of Gauge | Min. of Gauge | Max. of Gauge | 1100 | 3003 | 5005 | 5052 | 2024 | 6061 | 7075 |

| 1 | .249 | .238 | .260 | 3.52 | 3.56 | 3.52 | 3.49 | 3.60 | 3.53 | 3.623 |

| 4 | .190 | .181 | .199 | 2.69 | 2.71 | 2.69 | 2.65 | 2.77 | 2.69 | 2.763 |

| 6 | .160 | .152 | .168 | 2.27 | 2.28 | 2.27 | 2.23 | 2.32 | 2.25 | 2.327 |

| 8 | .125 | .120 | .130 | 1.76 | 1.78 | 1.76 | 1.75 | 1.82 | 1.76 | 1.818 |

| 10 | .100 | .095 | .105 | 1.41 | 1.43 | 1.41 | 1.40 | 1.45 | 1.41 | 1.454 |

| 11 | .090 | .086 | .094 | 1.27 | 1.28 | 1.27 | 1.26 | 1.31 | 1.27 | 1.309 |

| 12 | .080 | .076 | .084 | 1.13 | 1.14 | 1.13 | 1.12 | 1.16 | 1.13 | 1.164 |

| 14 | .063 | .059 | .067 | .889 | .898 | .889 | .880 | .916 | .889 | .916 |

| 16 | .050 | .046 | .054 | .706 | .713 | .706 | .698 | .727 | .706 | .727 |

| 18 | .040 | .037 | .043 | .564 | .570 | .564 | .559 | .582 | .564 | .582 |

| 20 | .032 | .0295 | .0345 | .452 | .456 | .452 | .447 | .466 | .452 | .465 |

| 22 | .025 | .0225 | .0275 | .353 | .356 | .353 | .349 | .364 | .353 | .364 |

| 24 | .020 | .0175 | .0225 | .282 | .285 | .282 | .279 | .291 | .282 | .291 |

| 26 | .016 | .014 | .018 | .226 | .228 | .226 | – | .232 | – | – |

| 28 | .012 | .010 | .014 | .169 | – | .169 | – | – | – | – |