Perforated Casing Tube

Holic® offers perforated Panels.Slotted/perforated pipes and tubes are common casing layer for pipe-core wire wrapped well screens. The perforated casing tube has round holes uniformly distributed for smooth flow of the liquid. It is actually a supporting pipe for sand control system in drilling oil or water wells. The metals are mostly stainless or mild steel.

How it Works: Perforated pipe or punched tubing is used as connection support. It links the wellbore and the producing formation through punched holes in the casing and the cement sheath that surrounds it.

Item Name: Perforated Casing Tube.

Brand: HOLIC®.

Product Description

Perforated Casing Tube

Holic® offers perforated Panels.Slotted/perforated pipes and tubes are common casing layer for pipe-core wire wrapped well screens. The perforated casing tube has round holes uniformly distributed for smooth flow of the liquid. It is actually a supporting pipe for sand control system in drilling oil or water wells. The metals are mostly stainless or mild steel.

How it Works: Perforated pipe or punched tubing is used as connection support. It links the wellbore and the producing formation through punched holes in the casing and the cement sheath that surrounds it.

Item Name: Perforated Casing Tube.

Brand: HOLIC®.

The size and distribution of perforated hoses pose a direct impact on well productivity.

Features:

- Available in J55 or N80. J55 and N80 have high strength and less potentiality of deformation.

- Punched hoses are smooth and clear without burrs.

- Easy installation.

- Overall preservative treatment creates a dense protective layer over the surface of the pipe and improves corrosive resistance.

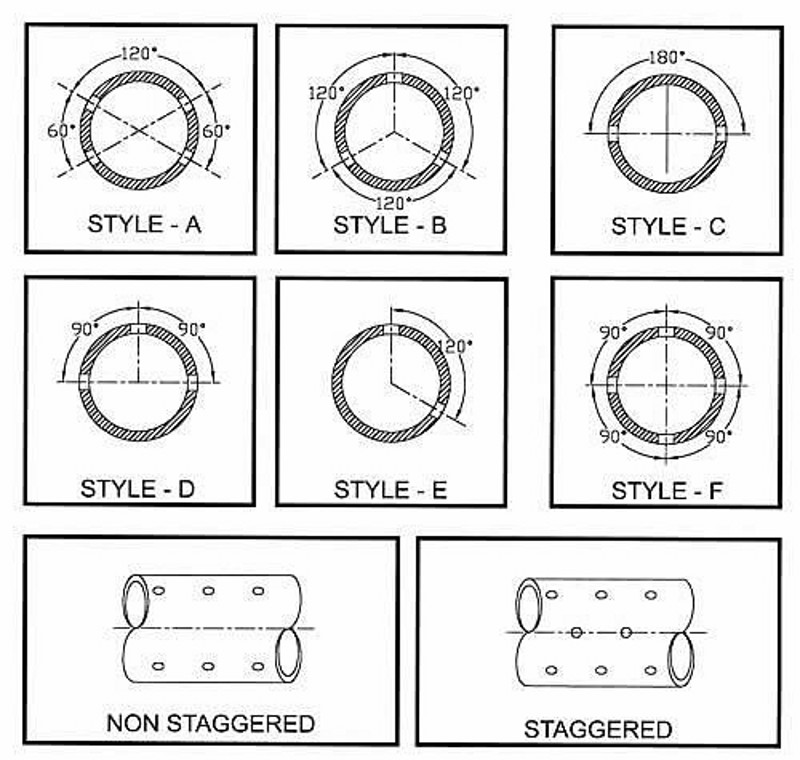

- Six types of punched hoses are available for specific application.

- Two types of hoses distribution are manufactured.

Punched Tube Hose types

Perforated Casing Pipe Specifications:

|

Pipe Size (inch) |

Number of hoses (sq in./ft) |

Hole Diameter (inch) |

Open Area (sq in./ft) |

|

3/4 |

78 |

3/16 |

2.15 |

|

1 |

54 |

5/16 |

4.14 |

|

1-1/4 |

66 |

5/16 |

5.06 |

|

1-1/2 |

78 |

5/16 |

5.98 |

|

2-1/16 |

78 |

5/16 |

5.98 |

|

2-3/8 |

90 |

3/8 |

9.94 |

|

2-7/8 |

102 |

3/8 |

11.26 |

|

3-1/2 |

126 |

3/8 |

13.91 |

|

4 |

138 |

3/8 |

15.24 |

|

4-1/2 |

150 |

3/8 |

16.56 |

|

5 |

162 |

3/8 |

17.88 |

|

5-1/2 |

174 |

3/8 |

19.21 |

|

6-5/8 |

186 |

3/8 |

20.53 |

|

7 |

222 |

3/8 |

24.51 |

|

9-5/8 |

294 |

3/8 |

32.46 |

Perforated Patterns

The majority of the patterns shown within each section represent the most commonly used patterns that our existing tooling produces. Due to the versatility of the tools and presses, it is not practical to show every possible pattern that can be produced. Because of the vast number of patterns that can be produced from our tools, it is likely that your requirement can be fulfilled with existing tooling.

In the event we can not produce a pattern with existing tooling, the Customer Service Representative will either quote the closest alternate and/or obtain the price to have our on-site tool and die shop build a proprietary tool.