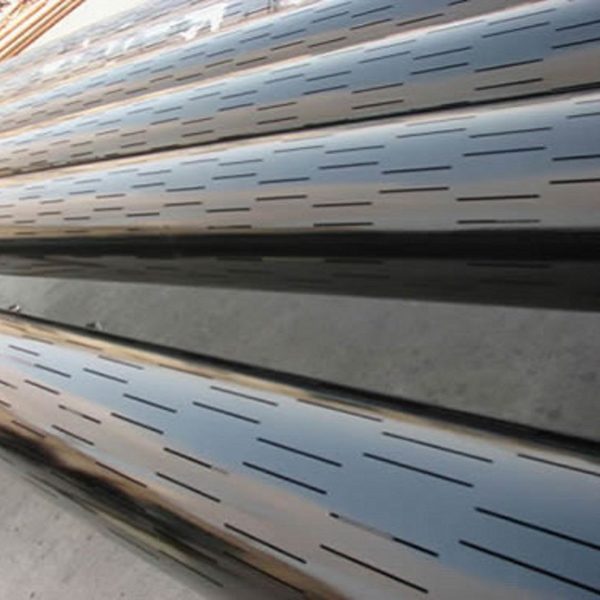

409 Stainless Steel Pipe/SS409 Tubing

Holic® offers 409 Stainless Steel Pipes and Tubes of ASTM A240M and ASTM A240.

If you desire a stainless steel whose mechanical properties highly outshine its physical appearance than 409 stainless steel is your perfect match. 409 Stainless is ideally used in scenarios where a need for oxidation or even corrosion protection is wanted. As a titanium stabilized ferritic stainless steel, 409 is most commonly used in automotive exhaust systems where the environment can be quite taxing on the lifetime of the steel.

Item Name: 409 Stainless Steel Pipe.

Brand: HOLIC®.

Standard: ASTM A240, ASTM A240M

Product Description

Type 409 Stainless Steel Pipe Factory:

Holic Oil Pipeline Co., LTD.

Type 409 Stainless Steel Pipe Basics:

If you desire a stainless steel whose mechanical properties highly outshine its physical appearance than 409 stainless steel is your perfect match. 409 Stainless is ideally used in scenarios where a need for oxidation or even corrosion protection is wanted. As a titanium stabilized ferritic stainless steel, 409 is most commonly used in automotive exhaust systems where the environment can be quite taxing on the lifetime of the steel.

Item Name: 409 Stainless Steel Pipe.

What is Stainless Steel Pipe?

Stainless steel refers to the alloy steel which can resist the corrosion of weak corrosive medium such as air, steam, water and chemical corrosive medium such as acid, alkali and salt. The corrosion resistance of stainless steel depends on the alloy elements contained in the steel. The basic alloy elements of stainless steel include nickel, molybdenum, titanium, niobium, copper, nitrogen, etc.

Stainless steel belongs to alloy steel, a kind of high alloy steel, which contains a lot of chromium, enough nickel and a certain amount of titanium. The role of chromium is to make the steel corrosion resistant, and the role of nickel is to reduce the austenitizing temperature of stainless steel. The total content of alloy elements can reach 10-28%, so it is a high alloy steel.

Advantages of stainless steel pipes

- Luster and Polishing surface

Our stainless steel is polished to ensure quality.

- Corrosion resistance

When the content of chromium atom in steel is not less than 12.5%, electrochemical corrosion can be prevented. Most stainless steel products are required to have good corrosion resistance, such as tableware, kitchen utensils, water heaters, water dispensers, etc. Some foreign buyers also test the corrosion resistance of the products.

- Excellent Solderability

Most of the finished products of stainless steel must have good weldability. Therefore, our stainless steel supplier can provide you with stainless steel with good weldability.

- Heat resistance

Stainless steel still has good physical and mechanical properties at high temperature.

Usage of stainless steel pipe

Although stainless steel pipes are higher cost to sources, according to its outstanding characteristics such as strength, anti rust, corrosion-resistance, stainless steel pipes have been applied in many industries and domains below

- Medical industry,

- Food and catering sector,

- Automotive and transportation industry,

- Construction and architecture domain,

- Energy and heavy industries.

Chemical Composition:

| Element | UNS S40910 | UNS S40920 | UNS S40930 |

| Carbon | 0.030 max. | 0.030 max. | 0.030 max |

| Manganese | 1.00 max. | 1.00 max. | 1.00 max. |

| Sulfur | 0.020 max. | 0.020 max | 0.020 max |

| Phosphorus | 0.040 max. | 0.040 max. | 0.040 max. |

| Silicon | 1.00 max. | 1.00 max. | 1.00 max. |

| Chromium | 10.5 – 11.7 | 10.5 – 11.7 | 10.5 – 11.7 |

| Nickel | 0.50 max. | 0.50 max. | 0.50 max. |

| Nitrogen | 0.030 max. | 0.030 max. | 0.030 max. |

| Titanium | 6x(C+N) min. – 0.50 max. | 8X(C+N)min. / 0.15 – 0.50 | 0.05 min. |

| Niobium | 0.17 max. | 0.10 max. | |

| Ti + Nb | [0.08+8x(C+N)] min. – 0.75 max. |

Mechanical Properties:

| Type | Yield Strength 0.2% offset (KSI) | Tensile Strength (KSI) | % Elongation (2″ Gauge length) | Hardness Rockwell |

| S40910 | 25 min. | 55 min | 20 min. | HRB 88 max. |

| S40920 | 25 min. | 55 min. | 20 min. | HRB 88 max. |

| S40930 | 25 min. | 55 min. | 20 min. | HRB 88 max. |

Fabrication

409 Stainless Steels provide good fabricating characteristics and can be cut, blanked and formed without difficulty. These steels provide fabricating characteristics that are much improved when compared to standard ASTM A240 Type 409 stainless steel. Brakes and presses used normally on carbon steel can be used on 409 Stainless Steels.

Welding

409 stainless is readily welded by arc welding processes. When gauge thickness and weld joint geometry permit the use of gas shielded metal-arc welding, joints having good properties are easily obtained. The electrode wires most often suggested are AWS ER309 or ER308L austenitic stainless steel when the application does not include exposure to high temperatures. AWS ER309 or ER308L stainless wire may also be employed for joining these stainless steels to mild steel. Thin wall components for elevated-temperature service should be weld fabricated with a matching weld filler such as 409 Cb. AWS ER430 and W18 Cr-Cb filler wires are suitable alternatives.

Our advantages:

As a leading brand of oil pipeline products in China, Holic® is working on providing high quality 409 Stainless Steel Pipes and Tubes with most competitive price.