ASTM A252 Steel Pipe Pile

Holic® offers ASTM A252 grade 1, 2 and 3 pipe pile. ASTM A252 is pipe piling material that used in constructions and structural, buildings. A252 standard specification includes three grades (1, 2, and 3), Grade 3 pipe piling material is the most used option.

Item Name: ASTM A252 Pipe Pile.

Brand: HOLIC®.

Standard and grades: ASTM 252. Grade 1, 2, and 3

Dimensions: Up to 48 inch seamless and welded

Types: Seamless, Welded (ERW, LSAW, SSAW, DSAW)

Thickness: Schedule STD, 40, XS, 80, XXS, 160

Length: 6m, 12m or customized.

Ends type: Plain end, Beveled.

Coating: FBE, 3PE, Galvanized.

Product Description

ASTM A252 Steel Pipe Pile Factory:

Holic Oil Pipeline Co., LTD.

ASTM A252 Pipe Pile Basics:

ASTM A252 is pipe piling material that used in constructions and structural, buildings. A252 standard specification includes three grades (1, 2, and 3), Grade 3 pipe piling material is the most used option.

Holic®supply ASTM A252 Pipe Pile Grade 1, 2 and 3 with below conditions:

Standard and grades: ASTM 252. Grade 1, 2, and 3

Dimensions: Up to 48 inch seamless and welded

Types: Seamless, Welded (ERW, LSAW, SSAW, DSAW)

Thickness: Schedule STD, 40, XS, 80, XXS, 160

Length: 6m, 12m or customized.

Ends type: Plain end, Beveled.

Coating: FBE, 3PE, Galvanized.

ASTM A252 Grade 3 – Common Pipe Piling Material:

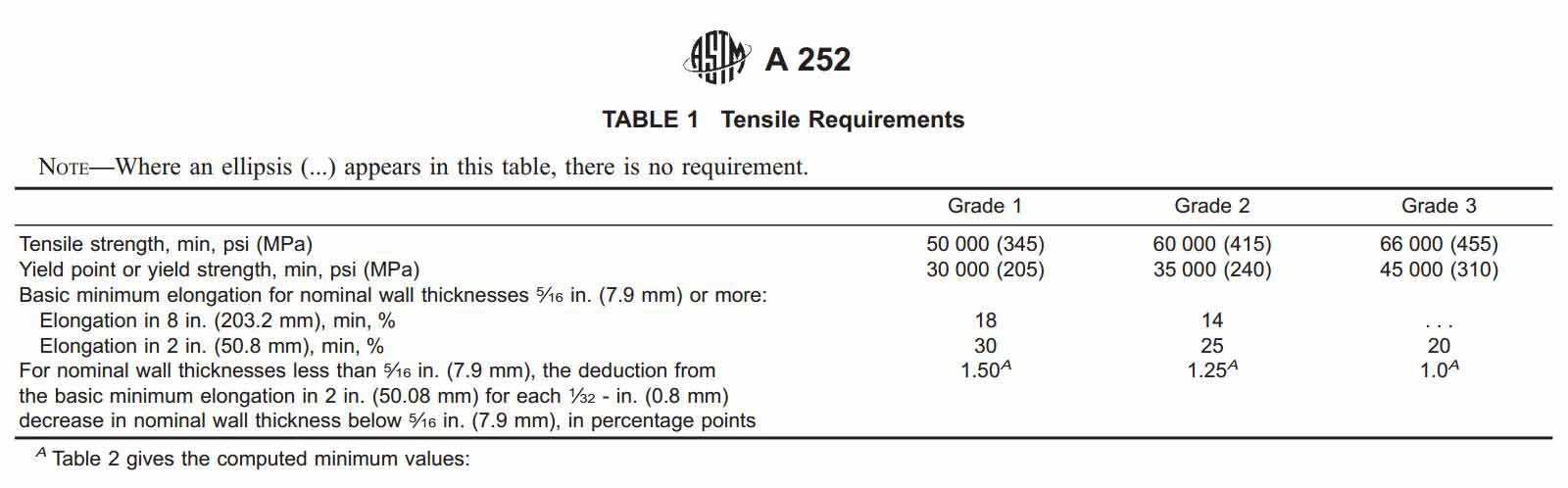

The most common pipe piling material is ASTM A252 Grade 3 pipe, this pipe grade could be made in seamless or welded, which in most situations are requested in welded type because of the large diameters pipe pile required. A252 Grade 3 has better strength which tensile in 455 Mpa (66,000 psi), and yield strength 310 Mpa (45,000 psi).

ASTM A252 Standard Scope:

ASTM A252 is the standard specification for welded and seamless steel pipe piles. It covers the nominal wall thickness of cylinder shape steel pipe, rectangular pipe is not included. These round pipes are used for piling purposes, playing as a permanent role of load carrying and bearing the pressure. Further more, to act as a tank shell to fill with the concrete piles at sight of the project.

This standard stated the values units in inch-pound (also could be translated to SI units), which provides the reference A252 pipe data to engineer or designer, for a strength base of the constructions.

Manufacturing types for ASTM A252 pipe pile:

ASTM A252 pipe pile manufactured types in seamless and welded.

Seamless pipe pile:

Seamless pipe pile includes manufacturing processes in hot rolled, cold drawn and thermal expanded seamless pipe.

Welded pipe pile:

Welded pipe pile referred as ERW (electric resistance welded), LSAW (Longitudinal Arc Sub-merged Welding) and DSAW/SSAW (Spiral Arc Welded Pipe).

Chemical composition and Mechanical Properties:

ASTM A252 allows a limit of phosphorous maximum at 0.050%, This is because P will make steel more fragile and break, further more higher P is not good for welding processes.

Test Methods:

- Heat Analysis: Limits P, heat analysis report shall be stated in MTC to customer.

- Product Analysis: Test frequency shall be adopted by the different pipe diameter, Specifically, under 14 inch 2 samples per 200 pieces, 14 to 36 inch 2 samples per 100 pieces, above 36 inch is 2 per 3000 ft.

- Tensile requirements: According the A252 value. In case got a vague yield point, then test yield strength corresponding to a permanent offset of 0.2% of the gage length of the sample specimen, or to test a total extension of 0.5% of the gage length under load.

Size and Weight Tolerance:

Tolerance allowed: OD tolerances at +/-1%, wall thickness +/- 12%. Weight shall be in +15% or -5% of theoretic weight.

Lengths: As specified SRL, DRL, or fixed length 20 ft or 40 ft and customized.

Hydrostatic Test:

Hydrostatic test is not specified in ASTM A252 pipe specification, as normally piling pipe is filling with cement and concrete and forming, not for liquid transmission, so hydrostatic is not required.

How Does Steel Pile Pipe Work

Steel pile is working under the conditions when the soil is loosely packed below the building and there might be a concern regarding the stability of the building over a period of time. When a pipe pile is used, the weight gets distributed evenly and into further depth inside the Earth, where the soil is tight. It is highly useful for the construction of super-large buildings where the soil fails to offer the required support.

On the other hand, in situations where the land area is small and does not give enough room for spread footers or foundations, the forcing buildings will be used so that there is a better level of stability on the ground.

Our advantages:

As a leading brand of oil pipeline products in China, Holic® is working on providing high quality ASTM A252 pipe pile (seamless & welded) with most competitive price.